Thermal efficiency in beanie materials is defined by the inverse...

A blended fabric beanie made from a combination of natural and synthetic materials for improved performance. This is a composite headwear solution engineered to optimize thermal regulation and durability by integrating distinct natural and synthetic fiber properties, ensuring it remains comfortable to wear and cool in warmer conditions. Blended fabric beanies are known for their breathability and warmth, making them a perfect garment for cold weather, especially when using pure natural fabrics. Solve the specific thermodynamic limitations found in single-fiber headwear by leveraging the “best-in-class” attributes of multiple polymers in a fiber combination to create a fabric that is also comfortable to wear. This composite approach creates a material that outperforms monocultural textiles in moisture management, tensile strength, and abrasion resistance.

Why Blended Fabric Beanies Solve the Thermodynamic Failures of Single-Fiber Hats

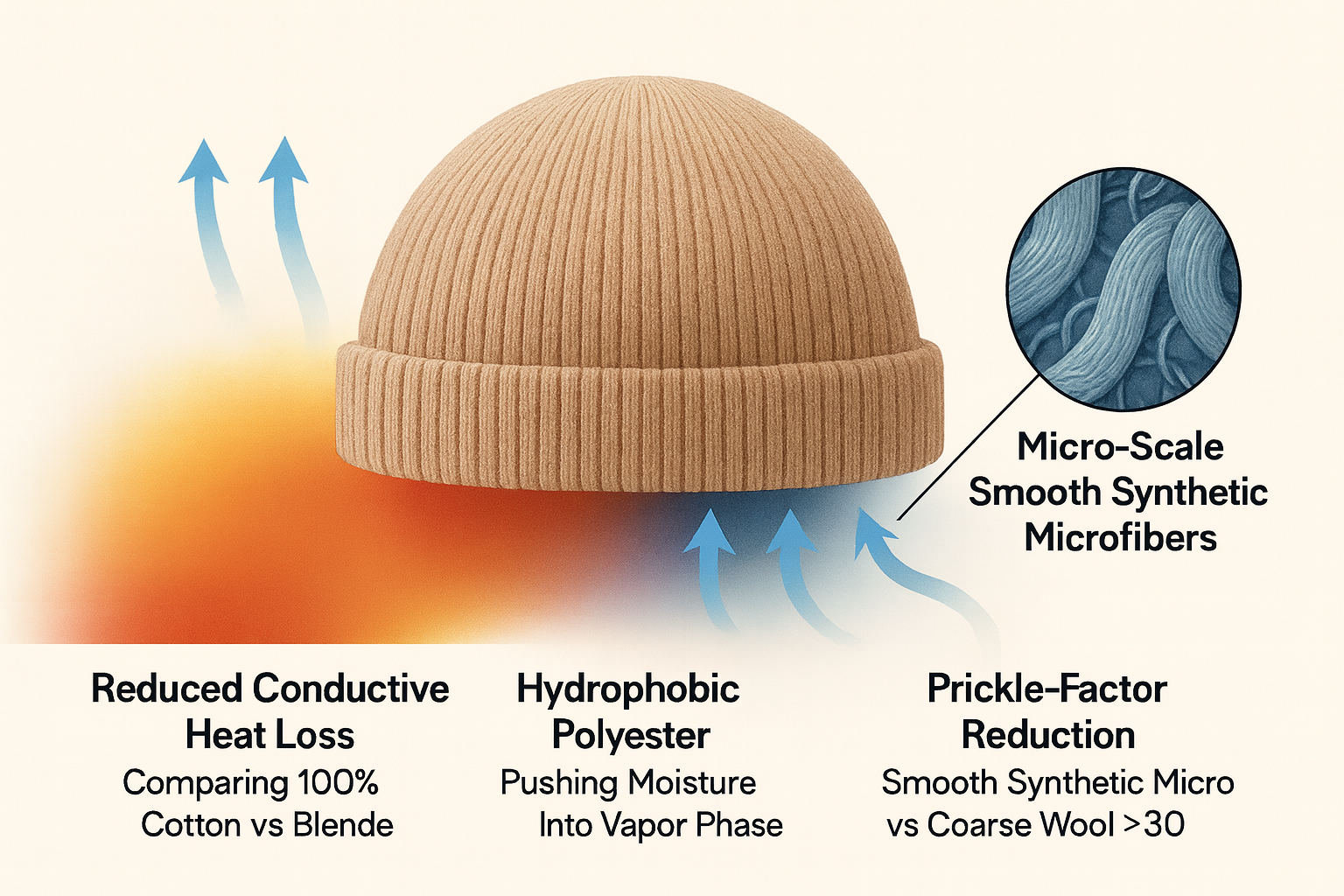

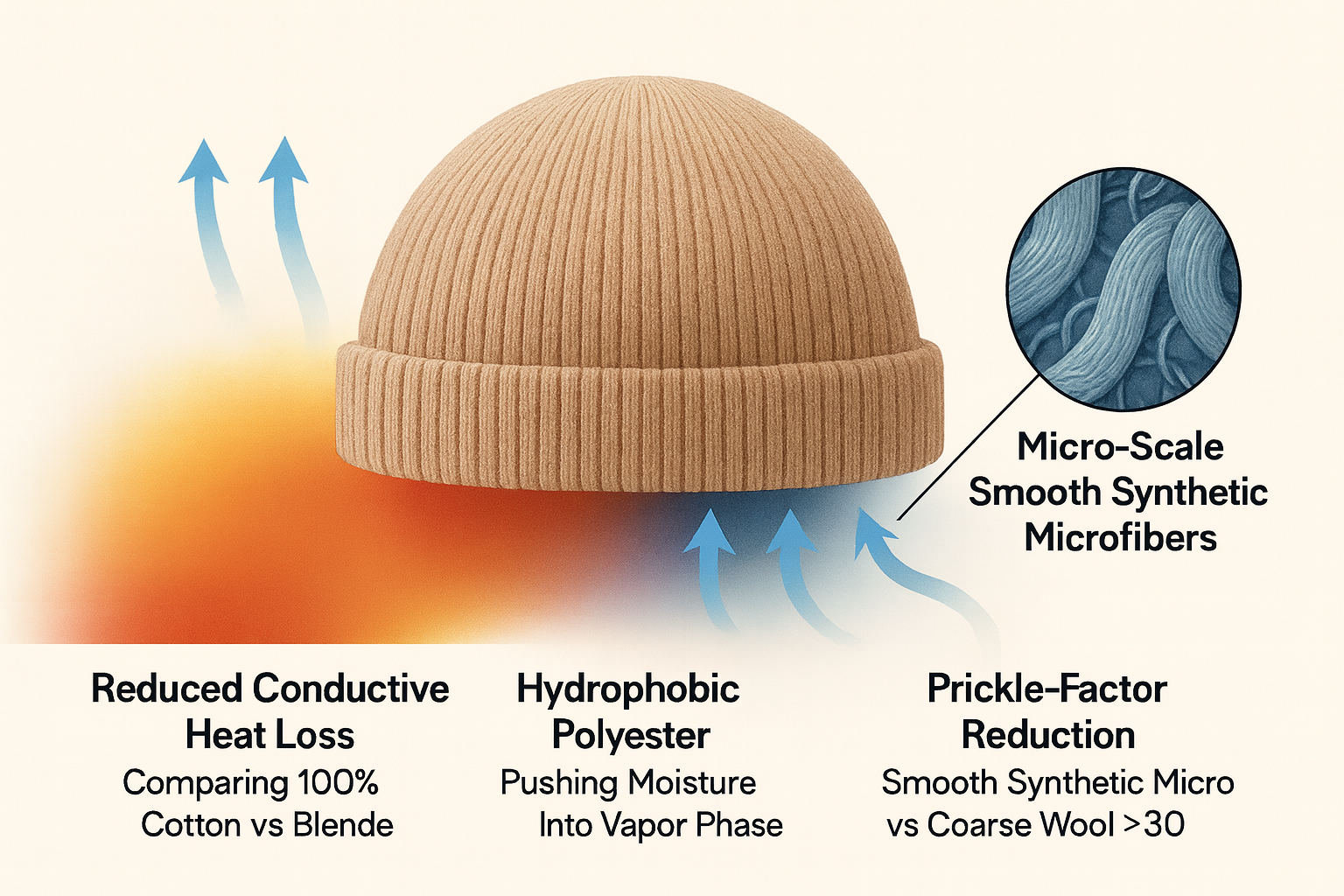

Blended fabric beanies Solve the thermodynamic failures of single-fiber headwear by integrating nylon hydrophobic fibers to prevent the rapid conductive heat loss inherent to 100% cotton or coarse wool, especially in blended materials. Hypothermia risks increase significantly if a wearer relies on single-fiber hydrophilic materials in wet-cold environments, making it crucial to use blended fabrics for better insulation and keeping you warm.

Quantifying Conductive Heat Loss in 100% Cotton

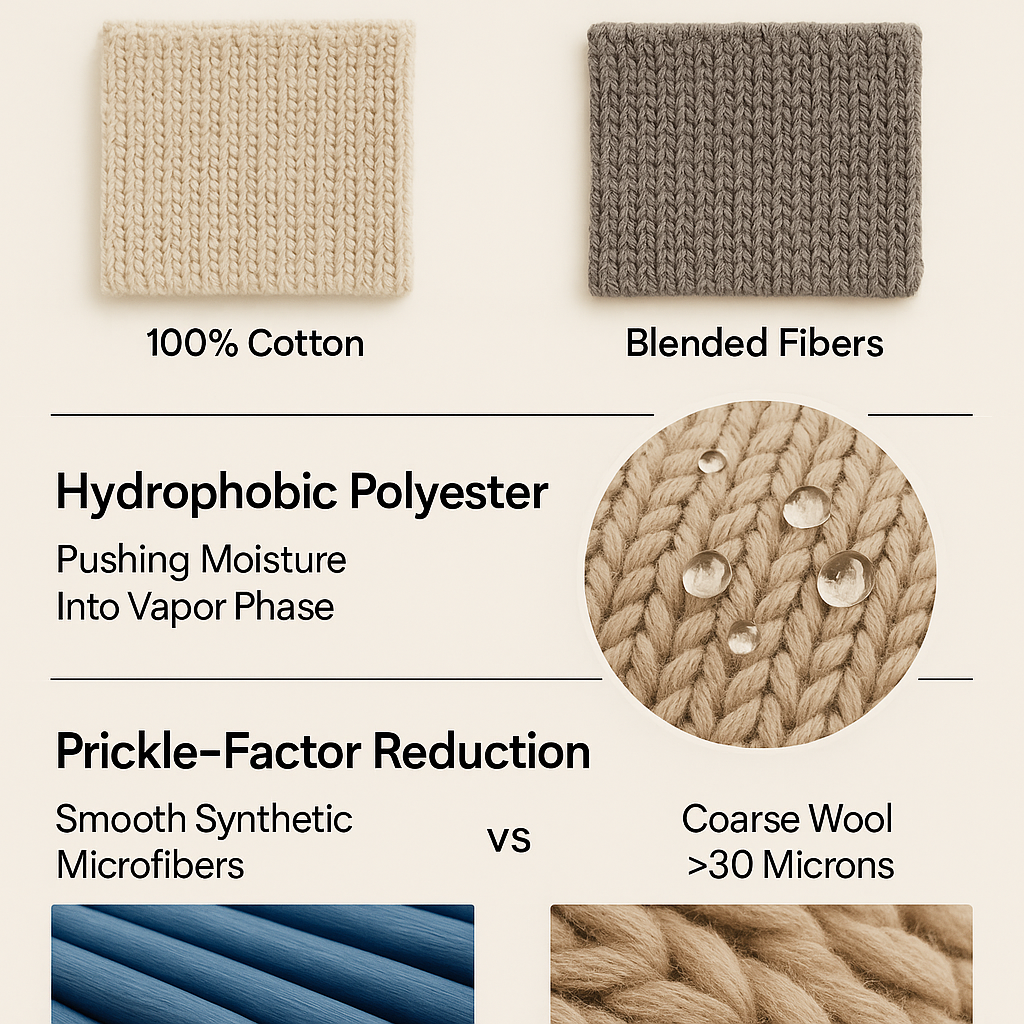

Blended fabric beanies prevent conductive heat loss by limiting the high cellulose content found in cotton, which contains hydroxyl groups that bond with water to increase thermal conductivity to 0.6 W/mK, especially in synthetic materials. Cotton fibers absorb up to 27 times their weight in water due to this molecular structure, making them a widely used fabric in various applications.

The saturation of inter-fiber air pockets increases thermal conductivity, which induces rapid hypothermic cooling, making the fabric efficient in temperature regulation and comfort while utilizing pure cotton or pure wool for optimal performance. Blended fabric beanies Disrupt this mechanism by reducing the available hydroxyl bonding sites, which can compromise the strength and durability of the fabric, especially in those containing linen and silk.

The “Prickle Factor” Threshold in 100% Coarse Wool

Blended fabric beanies eliminate the mechanical irritation known as “Prickle Factor,” which occurs in 100% wool when fibers exceed 30 microns and trigger Type C nociceptors (pain receptors) on the forehead. Blended fabric beanies Prevent the localized vasodilation (redness) and itch that affects approximately 43% of wool users by diluting coarse scales with a combination of natural and smooth synthetic filaments, ensuring a blend of organic cotton and polyester.

How the Hydrophobic Mechanism of Blended Fabric Beanies Works

Blended fabric beanies Utilize hydrophobic Polyester ester groups to generate zero hydrogen bonds with water, forcing moisture into the vapor phase for evaporation in a durable garment, enhancing its moisture-wicking properties. This hydrophobic mechanism rejects liquid phase bonding, which accelerates evaporation and maintains a dry thermal boundary layer next to the skin.

What Defines the Engineering Composition of a Blended Fabric Beanie?

The engineering composition of a fiber combination can significantly affect performance and comfort, especially when considering strength and durability. blended fabric beanie Is defined by its fiber architecture matrix, categorized technically as Intimate, Plated, or Core-Spun, with wool being a natural fiber contributing to its unique properties. This matrix dictates how the breathable fibers interact physically to manage heat and moisture, particularly when two types of fibers are involved.

- Mixes Fibers before carding to ensure Isotropic Homogeneity (Intimate Blend) are often derived from both natural materials and synthetic sources.

- Combines fibers to create a cotton-polyester blend that enhances durability and wrinkle resistance. hydrophobic interiors with hydrophilic exteriors to generate Push-Pull Mechanics (Plated Blend) enhance the comfort level of the fabric offers.

- Wraps are often made from durable materials to ensure longevity, especially when blended with cotton and polyester. A staple fiber sheath around a Spandex core provides Hysteresis Recovery (Core-Spun Blend) for a durable and comfortable garment made from blended fabrics that offer better durability and flexibility.

How Blended Fabric Beanies Use Differential Shrinkage to Create Loft

Blended fabric beanies create permanent insulation loft via differential shrinkage, where high-shrinkage Acrylic (20% boiling water shrinkage) forces the yarn to buckle against low-shrinkage Modacrylic (<3%). The resulting thermal mismatch creates a permanent crimp, which increases the Trapped Air Volume essential for insulation without adding mass, particularly when two types of fibers are used.

How Blended Fabric Beanies Use Specific Gravity for Structural Support

Blended fabric beanies maintain structural integrity by leveraging Polyester’s low Specific Gravity (1.38) to support heavier natural fibers like Cotton (1.54). Dimensional distortion (sagging) occurs under gravity if density ratios are unbalanced in heavy-knit headwear, which can affect the overall comfort of cotton blends and fabrics may require careful consideration of fiber composition.

How Blended Fabric Beanies Optimize Durability via Filament-Staple Combinations

Blended fabric beanies Optimize durability by combining continuous filaments with short staple fibers to create a cotton-polyester blend, a process that reduces yarn torque and prevents “spirality” in blended fabrics combine. Spirality is the tendency of a beanie to twist sideways after washing cycles due to residual torque in the yarn structure, which can be minimized by using a cotton-polyester blend that ensures durability and comfort.

How the Material Physics of Blended Fabric Beanies Improves Performance

The material physics of a variety of fabrics, including wool and silk, plays a crucial role in performance characteristics, as blended fabrics made from these materials offer unique advantages. blended fabric beanie translate the fiber composition into measurable performance gains in tensile strength, wicking velocity, and elastomeric recovery, utilizing a combination of at least two blended fabrics made from different fabric options. These metrics provide objective data points for evaluating headwear quality in a variety of fabrics, including those that combine the best of cotton and wool.

How Blended Fabric Beanies Maximize Aggregate Tensile Strength

Blended fabric beanies Maximize aggregate tensile strength by integrating Polyester (7.0 g/denier) to triple the modulus of elasticity found in Merino Wool (1.5 g/denier), ensuring the fabric is also resilient under stress and makes Merino Wool an excellent choice.

Shutterstock often features images of synthetic fabrics and cotton polyester blends used in various applications, showcasing their strength and durability as well as the uses of blended materials.

A 40% Polyester integration triples the modulus of elasticity, which prevents fabric rupture under the tensile stress of stretching the beanie over the head, enhancing the strength and durability of the fabric.

How Blended Fabric Beanies Increase Wicking Velocity

Blended fabric beanies demonstrate superior wicking velocity under AATCC Test Method 197, achieving rates of 1.5 cm/min compared to 0.2 cm/min for untreated cotton. The high capillary pressure in micro-grooved synthetics overcomes gravity to transport sweat rapidly to the evaporation surface, ensuring the fabric is also comfortable to wear.

How Blended Fabric Beanies Verify Elastomeric Recovery

Blended fabric beanies Verify elastomeric recovery via the “Elastic Limit,” allowing 500% elongation with 99% hysteresis recovery to original dimensions in breathable fabrics that combine the best of both worlds. This distinct “snap-back” capability ensures the beanie retains its fit after repeated use, contributing to its overall durability and softness.

How to Match Blended Fabric Beanie GSM to Your Metabolic Output

Selecting the correct fibers to create a durable and wrinkle-resistant garment is crucial for optimal performance. blended fabric beanie Requires matching the textile’s GSM (Grams per Square Meter) to the wearer’s Heat Generation (METs) when using synthetic blended fabrics that combine the best of both worlds for performance and comfort. Improper GSM selection results in overheating or insufficient insulation.

- Requires a durable design to withstand the rigors of daily wear and maintain its form. Poly-Spandex (<150 GSM) for High Output (>8 METs) like running.

- Requires Poly-Cotton (150-250 GSM) for Moderate Output (3-6 METs) like commuting.

- Requires Wool-Acrylic (>300 GSM) for Static Output (<2 METs) like camping.

Calculating Abrasion Resistance for Daily Wear of Blended Fabric Beanies

Blended fabric beanies Formulated for daily wear, often blended with synthetic materials, require a minimum 35% Polyester content to pass 20,000 cycles on the Martindale Abrasion Test (ASTM D4966), ensuring better durability. A 35% synthetic threshold ensures the fabric withstands daily friction without structural failure, while also enhancing its cotton content for better comfort.

Optimizing Insulation-to-Weight Ratios in Blended Fabric Beanies

Blended fabric beanies Utilizing Acrylic fibers optimizes insulation by providing 0.88 Clo/oz, which mimics wool warmth at 30% less weight, keeping you warm while ensuring the fabric offers durability and comfort. This ratio is critical for reducing pack weight in alpine environments, especially when using lightweight cotton-polyester blends.

Identifying Compression Requirements for Active Blended Fabric Beanies

Blended fabric beanies Designed for active use, fabrics may require 5% Elastane to generate the 4-Way Stretch necessary to resist G-forces while maintaining comfort and fit. Active headwear slips during movement if the elastic content falls below this threshold, particularly in synthetic fabrics.

How Do Blended Fabric Beanies Compare to 100% Cotton and Wool Options?

Blended fabric beanies offer a superior Cost Efficiency Index compared to 100% Cotton or Wool when analyzed via thermal resistance units and moisture regain percentages, making it an ideal choice for moisture-wicking apparel. Blends provide a balanced performance profile that single-fiber options cannot achieve.

How Blended Fabric Beanies Mitigate the “Cold Clammy” Sensation

Blended fabric beanies To mitigate the “cold clammy” sensation, use blended textiles that keep skin-side relative humidity below the 60% threshold where mechanoreceptors perceive dampness, especially in wool and cotton polyester combinations. Maintaining humidity below this physiological threshold prevents the perception of wetness even during active sweating, enhancing breathability in the fabric options used.

Analyzing the Cost-Benefit of Blended Fabric Beanies via Thermal Efficiency

Blended fabric beanies Utilizing Acrylic achieves 85% of Merino Wool’s thermal retention at 50% of the raw material cost, making it a cost-effective alternative in performance apparel compared to pure cotton fabric while maintaining durability and comfort. This efficiency derives from scalable polymer extrusion processes that mimic the natural fiber crimp structure found in wool fibers and other natural materials.

Comparing UV Resistance in Blended Fabric Beanies vs Natural Fibers

Blended fabric beanies Engineered with solution-dyed synthetics to block 95% of UV rays (UPF 50+) and rate Grade 5 on AATCC Colorfastness to Light tests, ensuring a durable garment with excellent moisture-wicking properties. Natural fibers, such as pure cotton and linen, often fade or degrade under prolonged UV exposure without heavy chemical treatments, affecting their durability and wrinkle resistance, especially when compared to synthetic blended fabrics.

How to Maintain Your Blended Fabric Beanie to Prevent Polymer Degradation

Maintaining a durable garment, such as a cotton-polyester sweater, is essential for long-term use. blended fabric beanie Necessitates strict adherence to temperature limits to prevent the hydrolytic degradation of synthetic polymers in durable garments, especially those made with cotton polyester, which is a widely used fabric. Proper care extends the functional lifespan of the durable technical fibers, keeping you warm during colder months and ensuring the comfort of cotton blends.

How to Prevent Hydrolysis in Blended Fabric Beanie Elastane Fibers

Blended fabric beanies containing Elastane suffer chain scission if exposed to water temperatures >105°F (40°C). Hydrolytic degradation occurs rapidly if hot water breaks the chemical bonds maintaining the fiber’s elasticity, particularly in breathable fabrics made from pure polyester, which are known for their comfort of cotton. Use Cold Water (<85°F) exclusively to preserve elastic modulus.

How to Avoid Agitation Felting in Wool-Blended Fabric Beanies

Blended fabric beanies with wool components undergo irreversible densification (Felting) if tumble dried with heat and mechanical agitation, while cotton-polyester blends maintain their structure better due to their synthetic fabric options. Tumble drying forces wool scales to ratchet together, permanently shrinking the beanie, which can affect the comfort of cotton blends. Static Air Dry (Flat) only to prevent this, especially when dealing with blended materials.

How to Store Blended Fabric Beanies to Prevent Pilling

Blended fabric beanies Develop pills (ASTM D3512) if friction against coarser fabrics forces fiber migration during storage, particularly in durable garments. Store blended textiles inside out to protect the durable technical face from abrasion and maintain the integrity of the fabric offers.

What Is the Final Technical Checklist for Buying a Blended Fabric Beanie?

The technical selection of a fabric blends is essential for achieving desired performance characteristics. blended fabric beanie A final audit of fiber dominance, insulation density, and elastic integrity is crucial for ensuring the durability and comfort of high-quality blended fabrics, particularly those made from wool and cotton polyester. Use the following checklist to verify technical specifications before purchase.

- Matches the softness and durability of pure fabrics while providing enhanced wrinkle resistance, especially in cotton polyester blends. Primary Fiber to metabolic need (Fiber Dominance) in a combination of natural and blended fibers context.

- Aligning the fibers in high-quality blended fabrics, including pure cotton fabric and wool, enhances breathability and comfort, making them ideal for various uses of blended garments. GSM rating with ambient temperature (Insulation Density).

- Lists of high-quality blended fabrics can help consumers choose the best options for their needs, particularly those that incorporate organic cotton and wool is a natural fiber. “Spandex,” “Lycra,” or “Elastane” >3% on the label (Elastic Integrity).

- Verifying the quality and performance of fabric blends in different environmental conditions is essential for selecting the best furnishing materials that combine the best attributes of various fibers. A “Singed” or “Combed” finish (Surface Texture) is often used in synthetic blended fabrics to enhance appearance and make them easier to care for.

After understanding blended fabric types, a logical side question is: what are common beanie material blends that include cotton content?