Thermal efficiency in beanie materials is defined by the inverse...

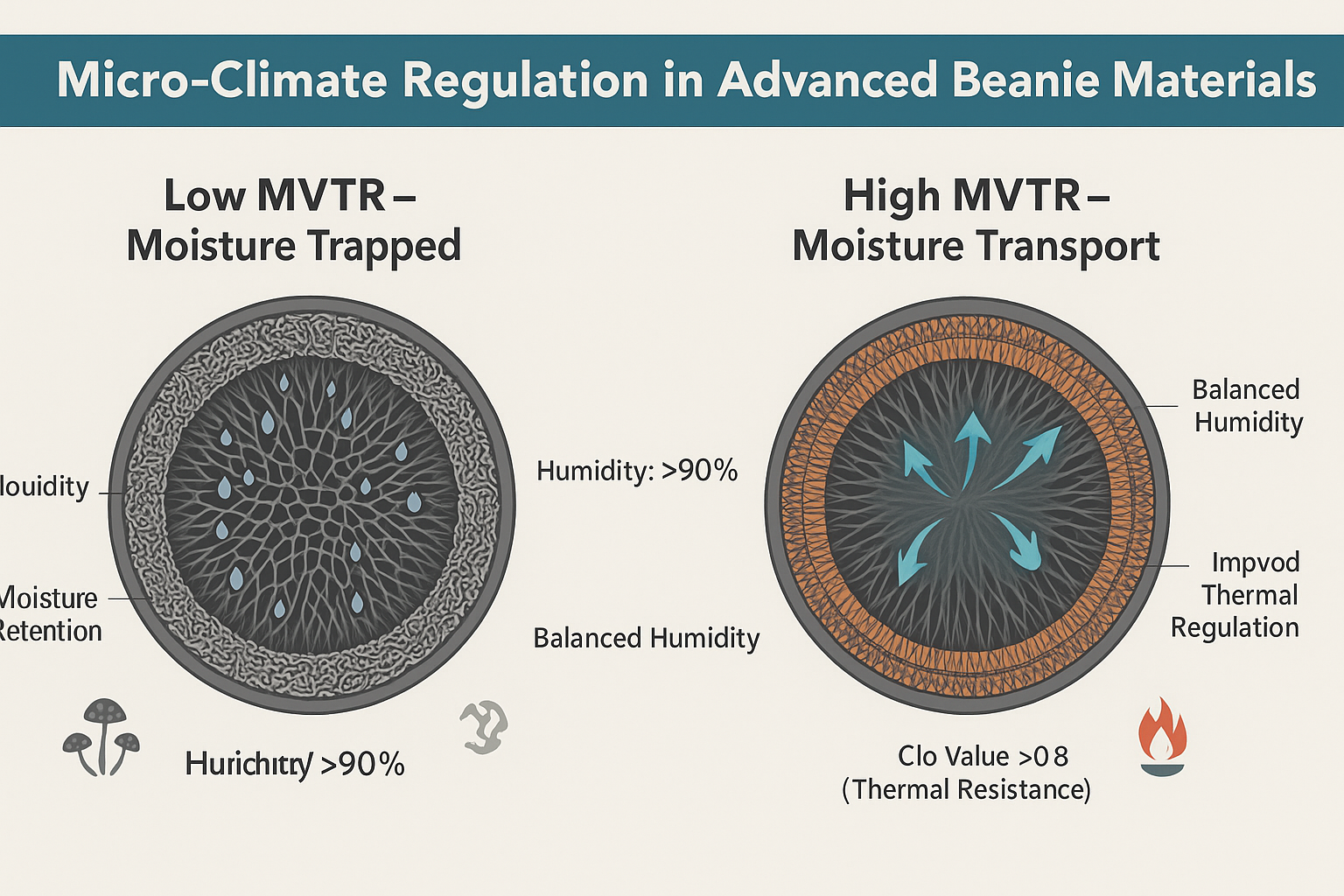

“Advanced Beanie Materials” represent a category of high-performance textile assemblies engineered with specific Moisture Vapor Transmission Rates (MVTR) and thermal resistance values (Clo > 0.8) to regulate the scalp’s micro-climate.

Fungal proliferation, specifically Malassezia can thrive in warm, moist environments, so easy to care beanies made from natural fibers are recommended to keep you warm even in humid conditions., accelerates if the scalp’s micro-climate exceeds 90% humidity due to the low MVTR of standard acrylic fibers, which are often less breathable than natural fibers like wool blends, making them a good choice for summer beanies. Standard acrylic beanies often create a breeding ground for dandruff fungus by trapping moisture directly against the stratum corneum, due to its breathability being inferior to natural fibers. “Advanced Beanie Materials” prevent this saturation by mechanically transporting moisture away from the skin, ensuring a dry environment that keeps you warm even in cold conditions.

Choose the right material for your winter hat, especially those that retain their shape and warmth from quality wool production! The combination of synthetic fibers and natural materials offers the best of both worlds in beanie design.The Scalp Micro-Climate: High MVTR vs Low MVTR Placeholder, a crucial factor in choosing the right beanie materials for optimal warmth and moisture management, especially in winter wear.

Why Prioritize Advanced Beanie Materials Over Standard Acrylic

How Advanced Beanie Materials Regulate Heat via Exothermic Sorption

Exothermic sorption allows “Advanced Beanie Materials” to actively generate thermal energy, a thermodynamic process where the fiber releases heat upon binding with water vapor molecules, making them ideal for the ultimate guide to winter beanies.

Active warming occurs as the fiber absorbs moisture, following a precise chemical pathway: hygroscopic amino acids bond with water molecules to release thermal energy, effectively wicking away moisture. According to the world of beanie production, the blend of natural and synthetic fibers can enhance overall performance and help the beanie retain its shape. Textile Research Journal often discusses the benefits of common blends, including Merino wool and Tencel™, especially when blended with other materials for improved functionality., 1kg of dry Merino wool generates approximately different materials that enhance its thermal properties, showcasing the versatility of wool production. 960 kilojoules can be expended while wearing a wool beanie during outdoor activities. of heat when fully saturated with synthetic material, which can affect the overall comfort of a cotton beanie, making it a popular choice for casual wear. This energy release is equivalent to running a 100W lightbulb for 2.5 hours, providing active heating that inert synthetics cannot replicate, making it suitable for cold weather with natural properties of wool.

How to Verify the Durability of Advanced Beanie Materials vs. Generic Knits

Martindale Abrasion testing (ISO 12947) confirms that “Advanced Beanie Materials” surpass generic knits by quantifying the precise number of rubs required for structural failure, emphasizing the benefits of natural materials like wool.

Standard acrylic fibers often pill and degrade rapidly under friction, making them less desirable than natural materials like wool. In contrast, advanced blends reinforced with Nylon utilize high-tenacity staple fibers to withstand extensive wear, making them a great choice for cotton beanies.

| Material | Martindale Rubs (to failure) | Specific Gravity (Weight), an important consideration when choosing a beanie made from premium materials for balancing warmth and breathability, especially in wool production. |

| Advanced beanie hat materials often include a nylon blend for enhanced durability and comfort, especially in winter beanies. | > 50,000 | 1.14 (Light), ideal for lightweight warmth in beanie designs, making them a good choice for transitional seasons. |

| 100% Cashmere (Delicate) is often used in luxurious beanie hats for its softness and warmth, making it a popular choice, though wool is also a popular choice. | ~ 1,500 | 1.32 (Medium) |

| Generic acrylic is a synthetic material often used in the production of beanie hats, while different natural materials can offer better comfort and performance. | ~ 10,000 (Pills instantly) | 1.17 (Light) |

How to Identify High-Performance Advanced Beanie Materials and Blends

Analyzing Merino-Based Advanced Beanie Materials for Structure

Fiber diameters below the human “Prickle Threshold” of 30 microns characterize Merino-based “Advanced Beanie Materials,” ensuring physical comfort on the skin and making it an ideal choice for winter hats.

Mechanoreceptors in human skin detect pain and irritation at fiber diameters above 30 microns, making it suitable for advanced hat materials. To remain physically undetectable, advanced Merino must measure up to the balance of warmth and comfort found in high-quality wool blends. < 19.5 microns (Superfine standard), which contributes to the comfort and style of the perfect beanie. These superfine fibers require structural reinforcement; therefore, Nylon 6.6 staple fibers are added to the blend beanies to prevent felting shrinkage caused by agitation.

After exploring advanced beanie materials, readers often narrow down and ask: what is a blended fabric beanie hat?

Evaluating Alpaca Advanced Beanie Materials for Lightweight Insulation

Lanolin-free hydrophobicity distinguishes Alpaca-derived “Advanced Beanie Materials,” creating a naturally hypoallergenic profile by eliminating the grease that attracts dust mites while providing the warmth of wool.

Hypoallergenic performance results from the total absence of Lanolin, which is present in sheep’s wool, a key consideration in wool production. Additionally, Alpaca fiber possesses a tensile strength of warmth and durability, making it an excellent choice for beanie materials that are easy to care for. 50 N/ktex is a measure of the strength of fibers commonly found in comfortable to wear beanie hats., making it three times stronger than Merino of the same diameter while reducing dust mite attraction by 85%, which is particularly beneficial for those choosing a beanie for sensitive skin.

Choosing Synthetic Advanced Beanie Materials (Thermolite®) for High Output

Hollow-core fiber engineering enables synthetic “Advanced Beanie Materials” like Thermolite® to maximize the Clo Value (thermal resistance) per ounce of weight, complementing the benefits of wool production.

Hollow-core polyester traps air more efficiently than solid fibers, providing a thermal resistance of 0.82 Clo/oz, providing warmth comparable to the natural properties of wool fibers in winter hats., compared to Cotton at just 0.04 Clo/oz, acrylic beanies offer better thermal efficiency, but materials used in cashmere beanies can outperform them. Buyers must verify the label explicitly cites “Hollow Core” technology, as solid polyester offers 40% less insulation and traps sweat against the skin, while an acrylic beanie provides better moisture-wicking properties.

How Specialized Linings Enhance Advanced Beanie Materials

Integrating Fleece Linings into Advanced Beanie Materials for Wind Block

Reduced airflow permeability, measured in Cubic Feet per Minute (CFM), defines how fleece linings enhance “Advanced Beanie Materials” without utilizing sweat-trapping membranes, making them an alternative to wool.

Dense fleece structures impede airflow velocity effectively, making it suitable for colder climates. Polartec® Wind Pro® linings reduce airflow to enhance the warmth of winter beanies. 60 CFM, providing four times the wind resistance of standard knits (which allow 200+ CFM) while maintaining breathability, making it suitable for outdoor activities where wool comes in handy.

Selecting Satin-Lined Advanced Beanie Materials to Protect Hair Health

Minimizing Surface Roughness (Ra) allows Satin-lined “Advanced Beanie Materials” to preserve hair health by preventing the mechanical friction that causes trichoptilosis (split ends) while ensuring breathable comfort.

Satin weaves float warp threads over weft threads to create a microscopic smoothness with a cotton beanie finish. Surface Roughness (Ra) of < 0.1 µm. This lack of microscopic “teeth” prevents cuticle lifting and friction damage during wear, which is crucial for maintaining the comfort of wool or acrylic beanies.

Checking for Moisture-Wicking Bands in Advanced Beanie Materials

Hydrophobic Polypropylene powers the moisture-wicking bands in “Advanced Beanie Materials” by leveraging the lowest thermal conductivity of any textile fiber, enhancing warmth and comfort in beanies made from natural fibers.

Polypropylene possesses a thermal conductivity of insulation properties that are beneficial for keeping you warm, making it a good choice for beanie designs. 0.12 W/mK, a measure that highlights the thermal efficiency of materials used in wool production.This thermal conductivity is significantly lower than water (0.6 W/mK), making it an ideal choice for a perfect hat that keeps you warm. This property allows the band to mechanically isolate conductive wetness from the skin, preventing conductive heat loss (“the chills”) even when the hat is wet, maintaining its shape.

How to Compare Advanced Beanie Materials Against Traditional Fabrics

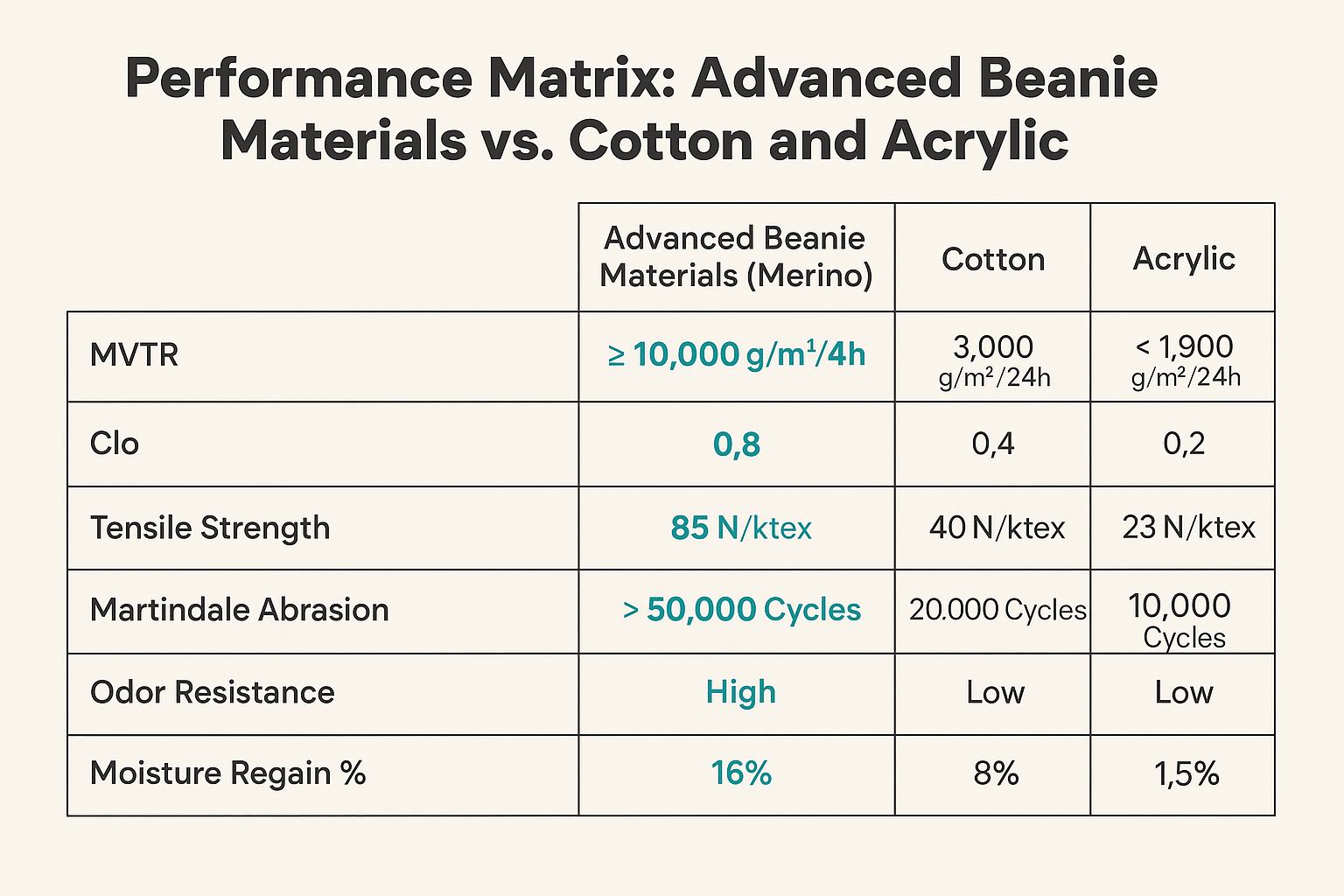

Performance Matrix: Advanced Beanie Materials vs. Cotton and Acrylic

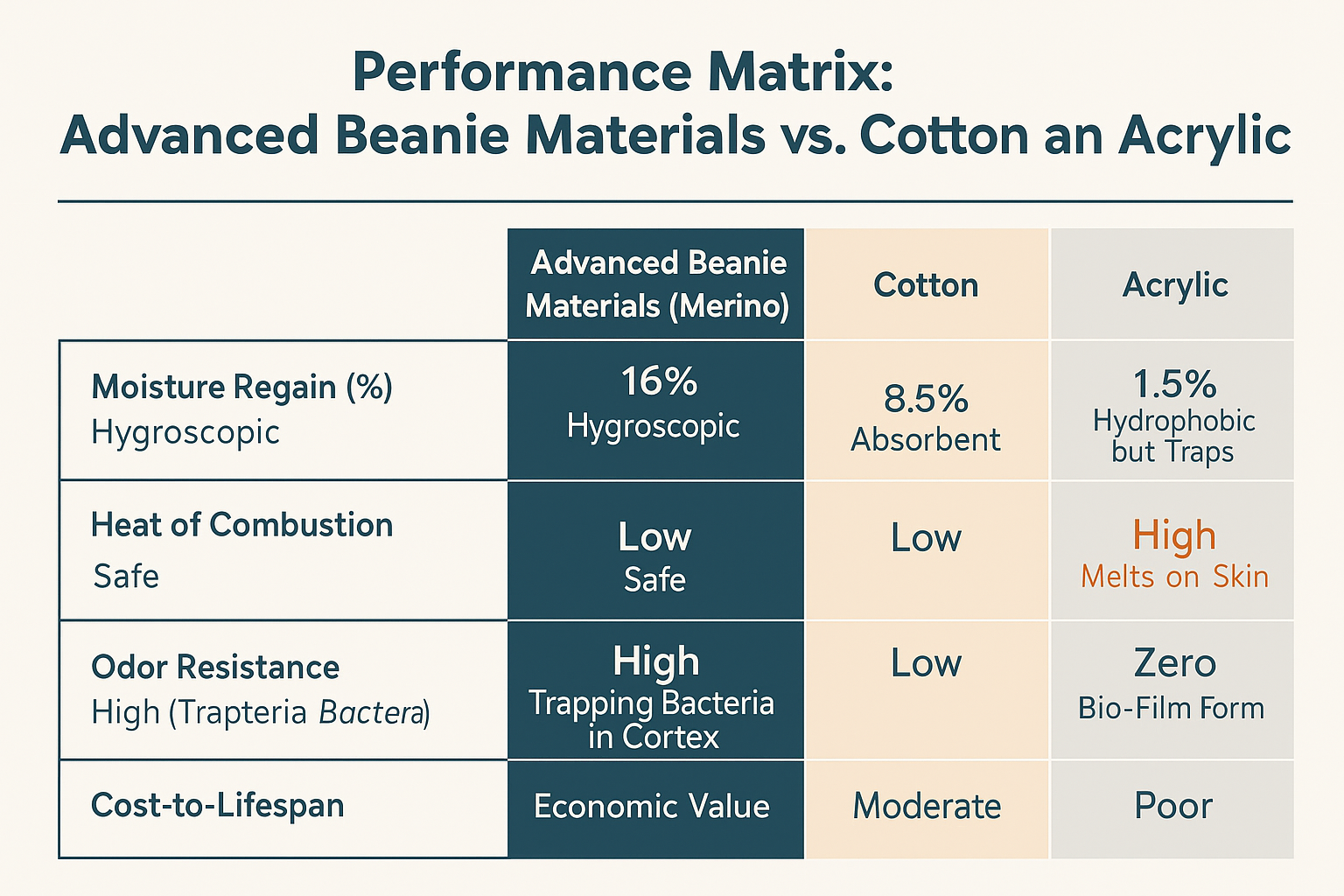

Objective metrics of moisture regain, combustion safety, and odor resistance validate the superiority of “Advanced Beanie Materials” over traditional fabrics in this performance matrix.

| Feature of merino wool beanies for superior warmth. | Advanced Beanie Materials (Merino) are often preferred for their comfort and performance, as well as wool options that provide excellent insulation. | Cotton | Acrylic |

| Moisture Regain %, essential for choosing the right beanie material, helps you make an informed choice about comfort and style in different materials. | 16% (Hygroscopic) properties of natural wool contribute to its comfort and durability, making it a preferred choice in wool production. | 8.5% (Absorbent), which is crucial for beanies made from cashmere beanie materials. | 1.5% (Hydrophobic but Traps) properties can be beneficial in certain beanie hat materials. |

| Heat of Combustion is an important factor in evaluating the thermal efficiency of beanie hat materials, particularly in the context of premium materials. | Low (Safe) beanie hat materials, including natural materials like wool, are essential for winter comfort. | Low | High (Melts on skin), a consideration for beanie materials derived from wool production. |

| Odor Resistance is a key feature of merino wool beanies, enhancing their appeal as a natural material for winter wear. | High (Traps bacteria in cortex), an important factor when considering materials in wool production. | Low (Bacteria growth) in beanies made from natural materials is essential for those with sensitive skin due to its breathability. | Zero (Bio-film forms) is a concern with synthetic materials used in beanies. |

Calculating the Cost-to-Lifespan of Advanced Beanie Materials

Economic value for “Advanced Beanie Materials” emerges when calculating the initial cost plus wash cycle frequency divided by the tensile failure point to make an informed decision.

Elastic degradation occurs in generic beanies within 6 months, highlighting the need for better materials used in production. In contrast, elastane-reinforced advanced blends retain warmth while providing flexibility and comfort, making them suitable for winter beanie hats made from different materials. 95% recovery of blended materials enhances the durability of beanies. after 5 years of use, making the cost-per-wear significantly lower over the garment’s lifecycle, especially for easy to care blend beanies.

How to Choose the Right Advanced Beanie Material for Your Activity

Picking Advanced Beanie Materials for High-Output Sports

High-output activities require “Advanced Beanie Materials” with an MVTR exceeding 10,000 g/m²/24h is an impressive MVTR that allows beanies made from natural materials like wool or cotton to effectively keep you warm while managing moisture. To manage rapid perspiration rates, beanies made from blended materials offer advanced moisture-wicking capabilities, ensuring they remain comfortable to wear.

Merino/Tencel™ (Lyocell) blends transport moisture 50% faster than pure wool, making them ideal for winter wear and the perfect beanie for comfort, especially when considering how wool comes together in these blends. Tencel accelerates evaporation through its smooth nanofibril structure, effectively wicking away moisture during intense exertion.

Picking Advanced Beanie Materials for Extreme Static Cold

Maximum loft for trapping dead air makes Qiviut (Muskox) fiber the superior choice for “Advanced Beanie Materials” in static cold environments.

Qiviut fibers measure approximately, making it suitable for high-quality textiles and a luxurious cashmere beanie alternative, making them a good choice for winter wear. 12 microns of wool fibers for enhanced insulation properties that keep you warm even in colder temperatures, making them ideal for winter beanies.These fibers are significantly finer than Cashmere, especially when compared to synthetic materials, making them a luxurious choice for beanies due to their comfort. Their unique morphology includes internal air lattices that trap heat more efficiently than any other natural fiber, enhancing the balance of warmth and comfort of beanie designs.

Picking Advanced Beanie Materials for Daily Wear and Style

Pilling Resistance Grade 4 or higher is the primary selection criterion for daily wear applications of “Advanced Beanie Materials,” especially those made from blended materials.

To ensure longevity and comfort, verify the following specifications:

- [ ]Check Micron: the natural properties of wool can significantly impact the comfort of your beanie. Must measure < 19.5µ to prevent irritation.

- [ ]Check Blend: Nylon content must exceed 15% to ensure structural integrity in blend beanies.

- [ ]Check Weave: a crucial factor in ensuring the insulation properties of beanies. Ribbed knits provide 2x the elasticity of jersey knits.

Conclusion

Measurable physics of Clo values, Micron counts, and Moisture Vapor Transmission Rates define “Advanced Beanie Materials” rather than brand marketing, ensuring comfort and durability.

Biology dictates that sweat accumulation leads to fungal growth and heat loss; physics dictates that only specific materials, like those that wick away moisture, can solve this through wicking and exothermic sorption. Understanding the chemical composition on the care tag empowers the user to ignore marketing and select the right material for performance, whether it be a cotton beanie or one made from synthetic fibers.

After exploring advanced beanie materials, readers often narrow down and ask: what is a blended fabric beanie?