Thermal efficiency in beanie materials is defined by the inverse...

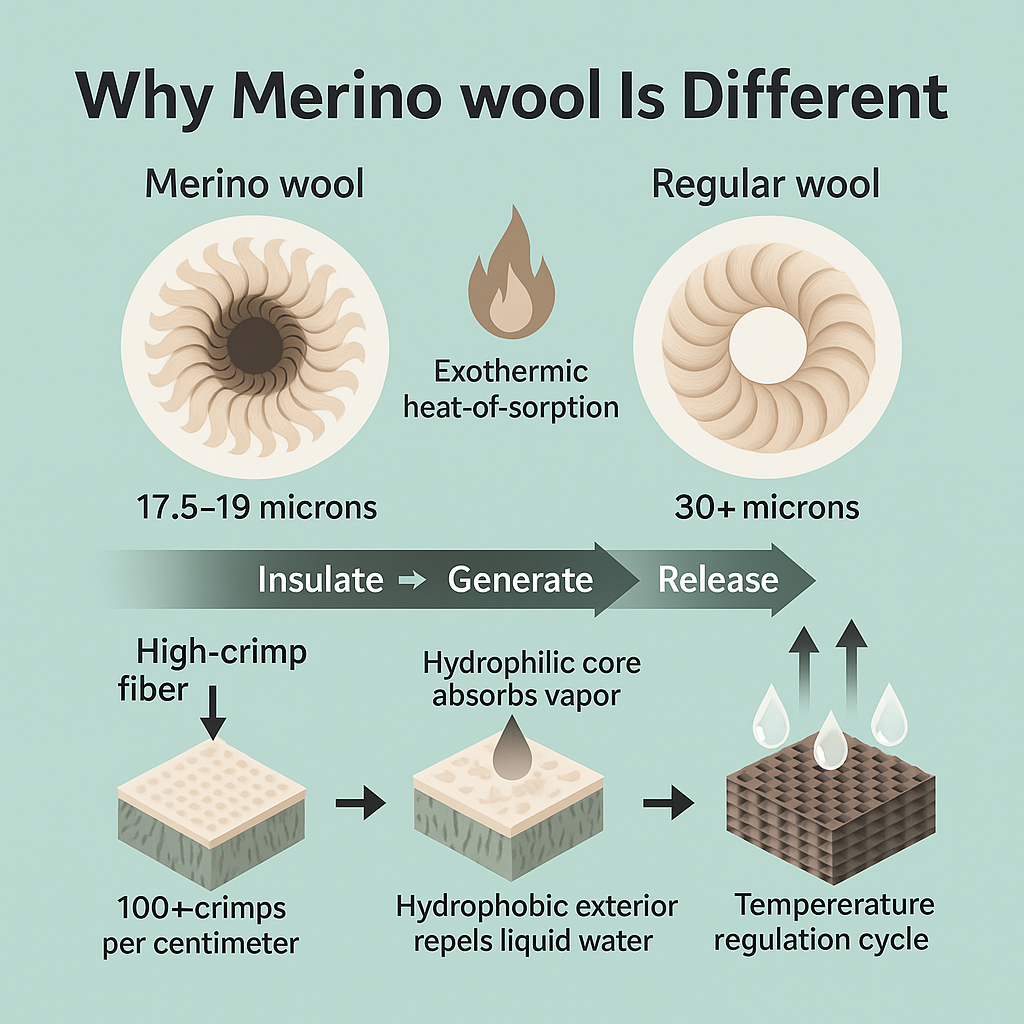

A Merino wool beanie distinguishes itself from synthetic headwear through a superior moisture regain rate of up to 35% and the ability to actively generate heat through exothermic chemical reactions, making it a top choice in the debate of merino wool vs regular wool. Unlike passive acrylic insulators, this performance garment functions as a dynamic regulator of the wearer’s microclimate, responding to humidity and temperature fluctuations with precise bio-chemical adjustments.

Why a Merino Wool Beanie Eliminates the “Itch” Factor

A Merino wool beanie eliminates the skin irritation inherent in traditional ragg wool because it utilizes fibers with a diameter between 17.5 and 19.5 microns, falling significantly below the human skin’s sensitivity threshold of 28 microns. The garment protects the forehead from abrasion by employing filaments that are physically incapable of remaining rigid enough to prick the hair follicle, allowing the fibers to remain close to the skin for comfort.

Analyzing the Micron Diameter of Merino vs. Traditional Wool

Textile physics dictates that comfort depends largely on the bend radius of the individual fiber, which affects how well it can breathe against the skin and contribute to moisture management. Standard wool fibers typically exceed 30 microns in diameter, creating a rigid, spear-like structure that resists bending upon contact with the stratum corneum, unlike the finer fibers of merino sheep. The Merino knit, conversely, employs ultrafine fibers under 19.5 microns that mimic the flexibility of silk threads, making it a superior choice compared to other types of normal wool, especially when merino wool comes into play. This specific diameter allows the filament to buckle harmlessly against the skin rather than penetrating the surface layer, resulting in a more comfortable and softer fit for indoors, particularly with merino wool comes.

Understanding the Hypoallergenic Nature for Sensitive Skin

The Merino fiber creates a hypoallergenic environment for sensitive skin because it lacks the coarse “guard hairs” found in standard sheep’s fleece that trigger contact dermatitis, making it ideal for temperature regulation. These beanies rely on a keratin protein structure that is biocompatible with human skin, avoiding the chemical sensitizers often found in the finishing agents of petroleum-based polymers, which can make regular wool itchy. A high crimp frequency—often reaching 100 crimps per centimeter—creates soft, aerated pockets that buffer the skin from direct friction.

Micro-Task Framework: Diagnostic Checklist

- The user requires a softer Merino wool beanie if current headwear leaves red friction marks on the forehead due to coarse fiber abrasion.

- A switch to <19.5 micron wool is necessary if the forehead skin itches within 15 minutes of wear due to a fiber diameter exceeding the 28-micron threshold.

- This garment serves as the correct technical gear if synthetic liners cause eczema flare-ups during perspiration by allowing moisture away from your skin.

Once skin comfort is assured, the fiber’s focus shifts to its active thermal regulation capabilities.

How a Merino Wool Beanie Generates Heat via Chemistry

A Merino wool beanie actively generates heat through a chemical process called the “heat of sorption,” where the absorption of moisture vapor into the fiber’s cellular structure triggers an exothermic reaction. The knit releases stored energy as perceptible warmth as humidity rises, acting as a buffer against cold, damp conditions rather than simply trapping existing body heat, much like the benefits of merino beanies.

Explaining the “Heat of Sorption” Reaction

Warmth generation occurs because hydrogen bonds forming between water molecules and the amino acids within the wool fiber release measurable energy, contributing to its insulating properties and creating air pockets that enhance thermal regulation. Textile science data indicates that 1 kilogram of Merino wool generates approximately as much heat as running an electric blanket for eight hours during this absorption phase, showcasing the benefits of this type of wool.

The beanie leverages this thermodynamic reaction to prevent “flash cooling” when the wearer stops moving in cold environments.

Managing Moisture Before it Becomes Sweat

The Merino fiber manages moisture through a dual-action structure where the hydrophilic The (water-loving) core extracts moisture away from the scalp while the beanie keeps the head warm. hydrophobic The water-repelling exterior of merino wool beanies resists external saturation, even in varying temp conditions. This complex architecture absorbs up to 35% of its own weight in moisture before feeling wet to the touch, enhancing the wick properties of the garment, which is a hallmark of best merino wool products. By sequestering vapor into the cortex of the fiber, the garment prevents the accumulation of liquid sweat that causes rapid evaporative heat loss, similar to how the best merino wool products function.

Micro-Task Framework: The Thermal Cycle, which can also include the use of merino wool base layers.

- Stage 1 (Insulation): The beanie insulates the head warm by trapping air within the fibers. The crimped fiber structure of merino wool beanies traps dead air to provide initial static insulation, which helps insulate the head in cold conditions, making them soft and warm, especially when merino wool comes from high-quality sources.

- Stage 2 (Generation): The fiber absorbs moisture vapor as the body sweats, initiating an exothermic reaction that generates active heat, particularly effective with merino wool in fluctuating temp environments.

- Stage 3 (Release): The beanie releases moisture away, keeping the head warm and comfortable, even in cold temp settings. The fabric releases moisture away from the atmosphere, cooling the head to prevent overheating, which enhances the breathable nature of the beanie and helps maintain optimal body temperature through effective knit construction.

Understanding this active thermal cycle clarifies the sharp distinction between biological fibers, like those from specific sheep breeds, and inert plastics.

What Distinguishes a Merino Wool Beanie from Acrylic Alternatives?

A Merino wool beanie differs from acrylic alternatives primarily through bio-reactivity, as the fiber contains fatty acids that degrade odor-causing bacteria, whereas acrylic beanies consist of inert plastics that support bacterial biofilms. The Merino knit offers superior hygiene and flammability profiles compared to its petrochemical competitors, making it a popular choice for icebreaker products that provide warmth and temperature regulation.

Comparing Odor Resistance (The “Biofilm” Factor)

Permanent odors are prevented in Merino garments because the fiber’s surface chemistry inhibits bacteria from organizing into the slimy, resistant “biofilms” that adhere to smooth synthetic fibers, unlike normal wool. The wool contains natural lanolin and complex fatty acids that break down the cell walls of odor-causing microbes. Field testing confirms that a Merino beanie sustains 10 or more wear cycles without washing, whereas an acrylic beanie often requires washing after a single high-output use due to immediate bacterial bloom.

Evaluating Flammability and Safety Specs

The Merino knit offers superior safety in backcountry environments because the fiber is naturally flame-retardant with an ignition temperature of approximately 570°C to 600°C, making it suitable for extreme temp adventures. The material self-extinguishes when the flame source is removed, thanks to its high Limiting Oxygen Index (LOI), making it a safer choice for wool beanies that come from specific sheep breeds, particularly those producing merino wool comes. Conversely, acrylic fibers melt at 160°C and fuel the fire, creating a severe hazard where molten plastic adheres to the skin and causes deep burns.

Micro-Task Framework: Comparison Matrix for evaluating material performance at different temp ranges.

- Warmth: A merino wool beanie is designed to keep you warm while also being breathable. The Merino beanie provides adaptive warmth through moisture regulation, while the bulky acrylic beanie traps sweat statically, unlike merino beanies that wick moisture effectively and keep you from getting cold.

- Odor: Merino wool doesn’t retain odors like synthetic materials, making it an excellent choice for active wear, especially in high temp activities. The Merino fiber resists odor for 10+ wears in an environmentally friendly manner, whereas the acrylic fiber develops bacterial odors after a single use, particularly in high temp situations.

- Safety: The Merino knit self-extinguishes at 600°C, while the acrylic fabric melts at 160°C.

Material composition dictates safety and hygiene, but selecting the correct fabric weight determines the operational range across various temp levels.

How to Select the Right Merino Wool Beanie GSM for Your Activity

Selecting the correct Merino wool beanie requires matching the Grams per Square Meter (GSM) rating to the user’s metabolic output to ensure it can keep you warm during outdoor activities, especially when the density of the fabric is optimized. A lower GSM facilitates rapid heat dumping for high-cardio efforts, while a higher GSM maximizes thermal resistance for static environments.

Deciding Between Lightweight (150 GSM) and Heavyweight (250 GSM)

A 150 GSM beanie optimizes performance for high-output activities like trail running by prioritizing moisture wicking and breathability over static insulation, making it a great choice for base layers. The lighter weave dissipates excess metabolic heat rapidly to prevent sweat buildup, especially in high temp scenarios. A 250+ GSM beanie traps more air per square centimeter, making it essential for low-movement activities like winter camping or urban commuting, especially when using merino wool beanies to keep the head warm. Textile analysis demonstrates that a 250 GSM knit construction provides nearly double the thermal resistance (Clo value) of its 150 GSM counterpart.

Choosing Between 100% Merino and Nylon Blends

Beanies featuring Core-Spun technology utilize a high-strength nylon filament core wrapped in merino wool to increase the garment’s burst strength and durability by approximately 40%, ensuring a longer-lasting hat. A 100% wool composition offers maximum softness but lower abrasion resistance compared to a blend of merino wool and polyester, particularly in extreme temp conditions. The nylon-core variation retains the hydrophobic/hydrophilic properties of the wool surface while extending the product’s lifespan against pilling and tearing, making it ideal for best merino wool products.

Micro-Task Framework: Decision Tree for selecting the right type of wool, ensuring merino wool comes as a preferred option.

- IF the beanie has a cuff, it can help keep the head warm in colder conditions, especially when paired with other merino wool base layers that provide warmth. The activity involves high cardio (Running/Skiing), where wearing a merino wool sweater can enhance comfort due to its moisture-wicking properties and less itchy feel, particularly in fluctuating temp. THEN, you might want to consider a soft and toasty merino wool sock that comes from a specific breed of sheep for added comfort. Consider purchasing a 150 GSM rating or a nylon blend that effectively wicks moisture away from your skin for enhanced comfort and moisture management.

- IF The activity involves static cold (Camping/Walking) in an environmentally friendly manner. THEN purchase a 250 GSM rating and 100% wool composition.

- IF The user prioritizes budget and longevity when selecting environmentally friendly wool beanies. THEN Consider purchasing a blend of merino wool and polyester to maximize durability in environmentally sustainable practices.

Proper selection of merino wool beanies ensures performance, but adherence to a strict maintenance protocol ensures longevity, especially for renewable materials.

How to Wash Your Merino Wool Beanie to Prevent Shrinking

A Merino wool beanie requires specific care using cold water and low agitation because heat and friction cause the fiber’s microscopic surface scales to interlock irreversibly, a process known as felting. The garment demands a gentle wash cycle to maintain its structural integrity and prevent the knit from seizing into a dense, non-elastic puck.

Preventing Felting During the Wash Cycle

Shrinkage occurs when hot water expands the fiber, allowing the directional scales to catch on one another during mechanical agitation, particularly in fabrics measured in microns at varying temp conditions. The beanie must be washed at temperatures below 30°C to keep these scales flat and smooth, which is crucial for maintaining the integrity of merino wool comes. A felted beanie made from normal wool loses its elasticity and thermal properties permanently, rendering the gear useless for providing warmth in colder conditions, while merino wool comes with superior insulation.

Avoiding Chemical Damage from Detergents

Standard laundry detergents damage Merino wool because they contain protease enzymes designed to digest protein-based food stains, compromising the quality and comfort of the fabric in an environmentally conscious way. These enzymes fail to distinguish between food proteins and the keratin proteins of the wool fiber, effectively digesting the fabric at any temp, which is why care must be taken when washing merino wool products. A pH-neutral wool wash, such as Nikwax, is required to clean the garment without degrading its structural protein bonds, regardless of the temp used in washing.

Micro-Task Framework: The Safe Wash Routine for merino wool comes to ensure optimal care.

- [ ]The user must turn the beanie inside out to protect the outer face from abrasion during the wash, especially when using finer merino wool that is designed to breathe.

- [ ]The detergent must be verified as free of protease enzymes to prevent fiber digestion, ensuring the quality and comfort of the merino wool, [ [ ]especially when merino wool comes from reputable sources and is used in various temp conditions.

- [ ]The washing machine must be set to a cold cycle to prevent thermal expansion of the fiber scales, ensuring the beanie material maintains its [ ]shape and the temperature is kept low for merino wool comes.

- [ ]The beanie must be laid flat to dry to prevent water weight from stretching the bulky knit structure, especially when using merino wool comes.

Once you see what sets merino apart, the next thing to explore is: what are the pros of a merino wool beanie?