Thermal efficiency in beanie materials is defined by the inverse...

Thermal efficiency in beanie materials is defined by the inverse relationship between fiber density and air entrapment in natural materials like wool and synthetic alternatives. To minimize conductive heat loss, one must evaluate beanie materials based on three specific metrics: Thermal Resistance (Clo value), Hygroscopic capacity, and Fiber Micron diameter, ensuring the best of both worlds in comfort and style. This analysis frames headwear physics to transition the reader from passive consumption to technical evaluation.

Why You Must Evaluate Beanie Materials for Insulation and Comfort

Explain How Beanie Materials Create Stationary Air Layers

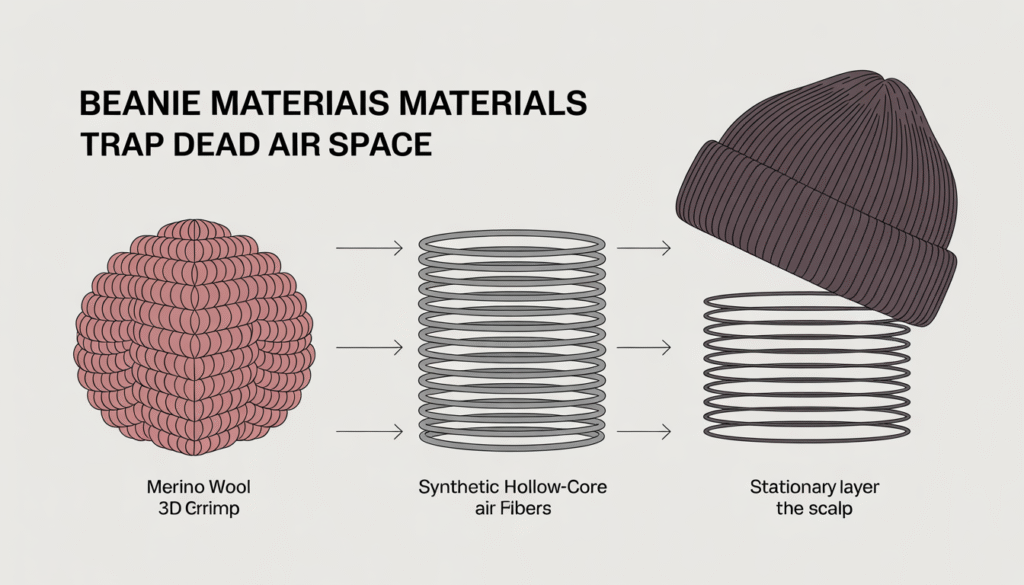

Beanie materials function by maintaining a layer of non-circulating air, known as Dead Air Space, adjacent to the scalp, especially in wool blend options. Insulation is defined as the entrapment of air within a fiber matrix, whether from natural fibers like wool or synthetic materials, rather than the generation of heat by the fiber itself.

- Wool Morphology: Merino beanie materials possess a 3D helical crimp, which enhances their natural breathability and insulation properties. This structure increases trapped air volume by approximately 60% compared to linear synthetic filaments.

- Synthetic loft is a key feature in beanies made from synthetic materials that mimic the properties of natural fibers. Polyester beanie materials rely on engineered hollow-core structures (e.g., Thermolite) to mimic the natural properties of wool, offering a synthetic alternative.

Master the Hygroscopic Exotherm Concept in Beanie Materials

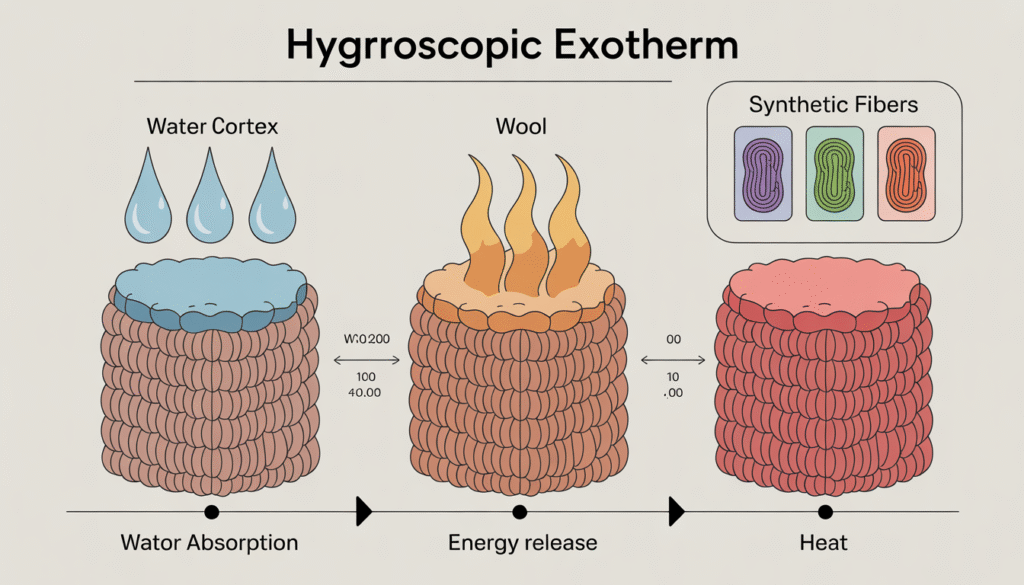

Specific beanie materials, particularly wool and blended materials, generate active heat through a chemical exothermic reaction when absorbing moisture vapor. Hygroscopic heat generation is a thermodynamic process where kinetic energy is released as water molecules bond to the fiber cortex, enhancing the natural properties of wool.

- Data Point: The best of both worlds can be achieved by combining natural materials for beanies with synthetic materials that mimic their properties in beanie production. 1kg of dry wool releases approximately 960 kilojoules of heat if saturated to 30% humidity, highlighting the benefits of wool beanies in thermal regulation.

- Comparison: Beanies offer various materials, including natural and synthetic options, to enhance warmth and performance. Synthetic beanie materials do not possess this exothermic capacity and remain thermally neutral during wetting, unlike natural materials like wool.

How to Analyze the Differences Between Natural and Synthetic Beanie Materials

Evaluate the Thermal Traits of Natural Beanie Materials

Natural beanie materials derive their thermal properties and skin-feel comfort primarily from the protein-based structure of Keratin, which is found in types of wool and is enhanced by recycled materials. Keratin is the fibrous structural protein that constitutes the cortex and cuticle of natural wool fibers, which are often preferred over synthetic materials for their superior properties of wool.

The Itch Threshold Scale helps determine the comfort level of various fibers used in beanies, including both natural and synthetic options, such as acrylic beanies which offer an alternative to wool.

| Fiber Type | Micron diameter is an important factor when selecting the right material for beanies, affecting their insulation properties. | Comfort Rating: The perfect beanie should balance comfort and style, incorporating natural fibers like cotton or wool. |

| Human Hair is a natural fiber that can be used in various textile applications, including beanies, providing benefits of natural warmth. | 50-70 microns | N/A |

| Traditional Wool, known for its warmth, is often favored for creating the perfect beanie, although acrylic is a synthetic material that can also provide warmth. | 30+ microns of wool production is essential for creating high-quality fibers in winter wear. | High Itch (Prickle) |

| Medium Merino | 21-24 microns | Moderate Comfort |

| Superfine Merino is a common blend that offers the benefits of natural warmth with added comfort, making it a popular choice for merino wool beanies and an excellent alternative to wool. | <18.5 microns | No Itch (Silk-like) |

Merino Wool: High comfort results if fibers measure <18.5 microns. These fibers bend upon skin contact to eliminate the prickle sensation.- Cashmere (Capra Hircus): Hollow-core microscopic structures offer 3x the insulation per gram of sheep wool, making them a premium material for winter wear. Durability is low due to reduced tensile strength in certain synthetic materials compared to natural fibers.

- Cotton (Cellulose): This is a popular choice for cotton beanies due to its breathability. Cotton beanie materials act as a heat sink due to high thermal conductivity (~0.07 W/mK), making them a good choice among breathable materials, but choosing the right beanie material for winter is crucial for warmth. Insulation collapses if the material absorbs water (up to 27x its weight).

Evaluate the Hydrophobic Traits of Synthetic Beanie Materials

Synthetic beanie materials utilize polymer-based fibers to repel moisture and maintain loft in wet conditions. Hydrophobic fibers are non-polar materials that lack the chemical capacity to bond with water molecules, making them ideal for the perfect hat.

- Acrylic (Polyacrylonitrile): Clamminess occurs because acrylic beanie materials lack an internal cortex to absorb moisture vapor. Sweat accumulates on the skin surface, which can be managed by using hydrophobic fibers in hats made from natural materials.

- Polyester Fleece (Polyethylene Terephthalate): This synthetic material is often blended with natural fibers to create the best of both worlds. Thermal efficiency remains high because polyester beanie materials absorb <1% of their weight in water. The material maintains 90% of its Clo value if wet, which is important for both cotton and wool blend beanies.

Assess the Engineering of Blended Beanie Materials

Blended beanie materials combine natural warmth, like that of sheep’s wool, with synthetic durability, and common blends include nylon for correcting the structural deficiencies of single-fiber fabrics. A structural blend is the intimate mixing of different fiber types during spinning to achieve specific performance characteristics, often by combining natural and synthetic fibers.

- Abrasion Resistance: Beanies made from synthetic fibers often exhibit superior abrasion resistance compared to natural materials. Merino wool durability increases if blended with 20% Nylon scaffolding.

- Elastic Recovery: This is crucial for both natural and synthetic fibers in beanie construction. Permanent deformation (sagging) occurs after ~100 load cycles if the beanie material lacks 2-4% Elastane.

How to Select Beanie Materials Based on Activity Levels

Match Beanie Materials to High-MET Activities (Running/Touring)

High-output activities require beanie materials that prioritize vapor pressure management over maximum insulation, especially when choosing the right beanie material for active use. Vapor pressure management is crucial in breathable textiles, allowing beanies made from different materials to transport moisture effectively from skin to the atmosphere.

- Selection: Choosing the right beanie material is essential for comfort and performance. Select 100% Polyester or Lightweight (150gsm) Merino beanie materials, as these synthetic materials provide excellent durability compared to synthetic fibers.

- Physics: the study of materials can reveal the best options for creating the perfect beanie. Rapid evaporative cooling stops if thick beanie materials create a vapor barrier. A high Moisture Transmission Rate (MTR) is essential.

Match Beanie Materials to Static Low-MET Activities (Standing/Belaying)

Static activities require beanie materials with maximum Thermal Resistance (Clo), such as wool beanies, to preserve body heat, especially when compared to synthetic fibers. Thermal Resistance (Clo) is the measurement of a material’s ability to block the transfer of heat, which is crucial for beanies made from wool.

- Selection: Choose Heavyweight Wool (300gsm+) or High-Loft Acrylic beanie materials, as material is key for comfort and durability.

- Physics: Heat retention relies primarily on mass and loft in low-energy states.

Consult the Beanie Materials Decision Table

Use the following data matrix to align beanie material selection with specific metabolic energy expenditures (MET) to ensure the perfect hat for any activity, considering premium materials like wool and synthetic options.

| Activity Level | MET Score and the natural properties of wool are important factors to consider when selecting a beanie made from natural materials. | Recommended Beanie Material includes options like wool production blends and synthetic materials such as polyester. | Target GSM (Weight) |

| High Output with different materials, such as wool or cotton, can enhance performance in various conditions. | > 6.0 | Polyester / Thin Merino | 150-200 gsm is a common weight for blended material beanies. |

| Moderate | 3.0 – 6.0, which includes materials like wool and cotton beanies. | Merino Blend (Nylon mix) is one of the common blends used in perfect beanie designs, combining the advantages of different types of wool with synthetic materials. | 200-250 gsm |

| Static | < 1.5 | Heavy Wool / Acrylic | 300+ gsm is often recommended for beanies made from wool to ensure maximum insulation. |

How to Compare Beanie Materials Using Performance Data

Review the Beanie Materials Technical Performance Matrix

Analyzing beanie materials through a comparative matrix reveals the trade-offs between conductivity, moisture regain, and the benefits of natural fibers like sheep’s wool. A performance matrix is a comparative tool used to normalize qualitative attributes into quantitative data points for hats made from natural and synthetic materials.

| Metric for evaluating beanie materials includes factors like warmth of wool, types of wool, and synthetic durability. | Merino Wool | Acrylic | Cotton | Polyester Fleece |

| Thermal Conductivity is a critical factor in determining how effectively materials like wool offer insulation. | Low (Insulator) materials like acrylic are a common choice for those who are allergic to wool. | Moderate | High (Conductor) | Low (Insulator) |

| Moisture Regain % | 13-17% (Hygroscopic) moisture retention is a key property of wool fibers used in beanies. | 1.5% (Hydrophobic) | 8.5% (Hydrophilic) | 0.4% (Hydrophobic) |

| Odor Bacteriostasis is an important factor when selecting beanie materials, especially those blended with other materials. | High (Chemical) | Low (Surface Growth) can impact the properties of natural fibers used in beanies. | Moderate | Low (Requires Silver) |

| Wet Insulation made from synthetic materials can lead to increased risks of hypothermia, unlike hats made from natural materials. | 80% Retention | 90% Retention | 0% (Negative) – This can be an issue for acrylic beanies. | 95% Retention |

Analyze Beanie Materials Failure Scenarios to Avoid Mistakes

Critical performance failures occur if beanie materials, such as synthetic fibers or natural materials, are mismatched to the environmental conditions. A failure scenario in textiles is defined as the inability of a material, such as those made from synthetic fibers, to perform its intended protective function under stress.

- Scenario A: Choosing a beanie made from synthetic fibers can offer enhanced performance and durability in extreme conditions. Hypothermia risks increase if cotton beanie materials are used in alpine conditions, making the warmth of wool, especially when blended with common blends that include acrylic fibers, a safer choice. Conduction increases 24x if air gaps are replaced by water.

- Scenario B: This scenario can be applied to both acrylic beanies and those made from natural fibers like wool. Dermatitis triggers if coarse wool beanie materials (>28 microns) penetrate the stratum corneum.

How to Buy the Best Beanie Materials (Final Checklist)

Download the Beanie Materials Shopping Card

Save this graphic to audit beanie materials quickly during the purchasing process, especially when considering the ultimate guide to hat materials.

Audit the Fiber Composition Label of Beanie Materials

Verify the quality of beanie materials by strictly auditing the manufacturer’s composition tag to ensure they include natural materials for beanies. The composition label is the legal declaration of fiber content required by textile trade regulations.

- Pass: This is a standard for evaluating both natural and synthetic materials for your hat, including beanies made from synthetic fibers. “100% Merino Wool” or “100% Recycled Polyester” are common blends that highlight the benefits of natural materials, offering warmth and durability as well as wool.

- Fail: Not considering the right material for a beanie, such as the alternative to wool, can lead to discomfort. “Winter Blend” (undefined) or >20% Cotton.

If you’re starting with beanie types, the next step is: what are natural beanie materials — key fibers, performance, and suitability?

- Fail: Not considering the right material for a beanie, such as the alternative to wool, can lead to discomfort. “Winter Blend” (undefined) or >20% Cotton.

Perform the Elastic Hysteresis (“Snap”) Test on Beanie Material

Test the longevity of beanie materials by measuring the elastic recovery speed of the cuff. Elastic hysteresis is the difference in energy required to stretch a material versus the energy released when it relaxes.

- Action: Choose the right material for your beanie, whether it’s a wool blend or made from natural fibers, to ensure optimal performance and comfort. Stretch cuff to 150% width and release.

- Pass: Immediate recovery occurs (Elastane matrix intact).

- Fail: Plastic deformation occurs (Cheap Acrylic).

Confirm the Micron Count (“Itch” Test) of Beanie Materials

Assess the comfort of natural beanie materials, like cotton, by testing fiber diameter against the inner wrist. The itch threshold is the specific fiber diameter (typically >28 microns) at which a nerve response is triggered by skin contact.

- Pass: Frictionless glide occurs if fibers are <18.5 microns.

- Fail: Prickle sensation occurs if fibers are >24 microns.

Finalize Beanie Materials Choice Based on Thermodynamics

The final purchase decision relies on a binary thermodynamic choice regarding moisture handling.

- Buy Hydrophobic Synthetic Beanie Materials if high sweat output is expected, beanies made from synthetic fibers can provide better moisture management.

- Buy Hygroscopic Wool Beanie Materials If dry cold conditions are expected, the warmth of wool provides the benefits of natural insulation that is particularly beneficial, much like a wool sweater.